Project Description

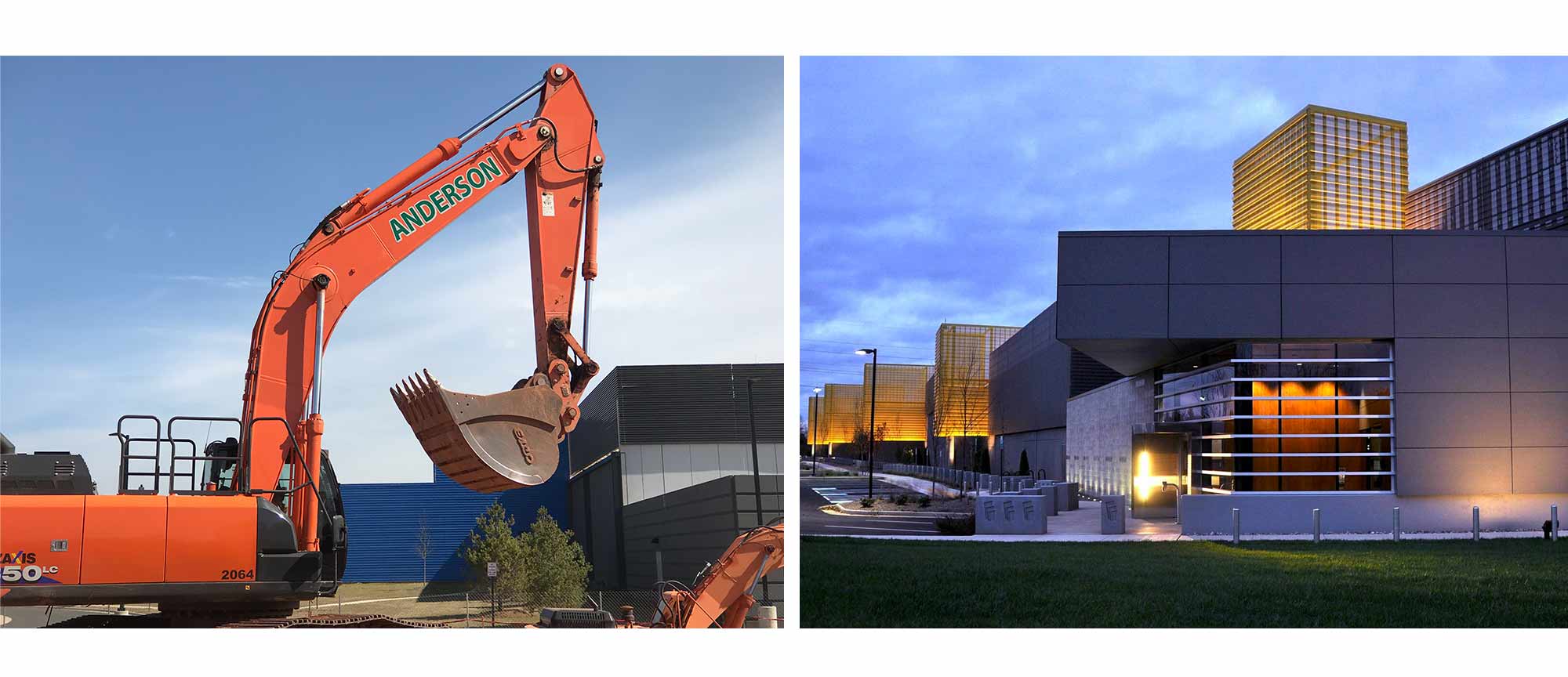

RagingWire Data Centers, Ashburn, VA

Located in the heart of “Data Center Alley”, RagingWire’s 78-acre high speed data center campus requires high speed development.

The Metropolitan DC area and, in particular, Northern Virginia, has fast-become a critical backbone to the nation’s seemingly insatiable digital appetite. By just about any estimation, the region is undergoing an unprecedented data center building boom that shows no signs of abating.

The Anderson Company (TAC) has been a key player in facilitating this phenomenon, most recently in the ambitious new Raging Wire development in Loudoun County.

Planned as a campus of seven buildings, TAC already has completed the site work for the first building including excavation, water, sanitary, storm, gutter work and utilities.

“We don’t meet change requests with protests – we just get the work done.”

But as Jochen Dunville, senior project manager, will tell you, data center work is highly unique because of its ultra-dynamic, fast-changing requirements.

“While the buildings themselves aren’t particularly complicated, the construction schedule for these projects is extremely aggressive,” says Dunville. “Normally you’d be asked to move 200,000 to 400,000 cubic yards of dirt in 18 to 24 months. But because of the demand for their services, that will get truncated down to 9 to 12 months.”

The other trait that sets data centers apart are the abrupt and often dramatic change orders. “These are almost all design-builds,” says Dunville. “You’ll be half-way through the job and a new plan will emerge.”

Such was the case with Raging Wire, where the owner – after building one was completed – opted for a different fiber to connect the campus. This required TAC to conduct new blasting and trenching for two miles’ worth of 6 x 8-foot ducts through the existing infrastructure.

“We move earth faster and more safely than any other company in the area.”

Which is what, in the estimation of Larry Neal, sets TAC apart from its competition. “We don’t meet change requests with protests – we just get the work done. And we do it by moving more earth faster and more safely than any other company in the area.”

Both Dunville and Neal credit TAC founder Jim Anderson’s commitment to fielding only the latest and most modern equipment with enabling the company to accomplish what it does in the time that it does while maintaining an industry-leading safety rating.

“At 7,000 hours, the equipment is replaced, and that starts with Mr. Anderson,” says Neal. “The trucks are cleaned every day and when they show up on the job site you can see the difference with equipment from other companies.”

TAC also deploys a mobile repair rig to minimize any potential downtime. If a truck or piece of equipment needs servicing, TAC dispatches the mobile repair unit to fix it and get it back online immediately.